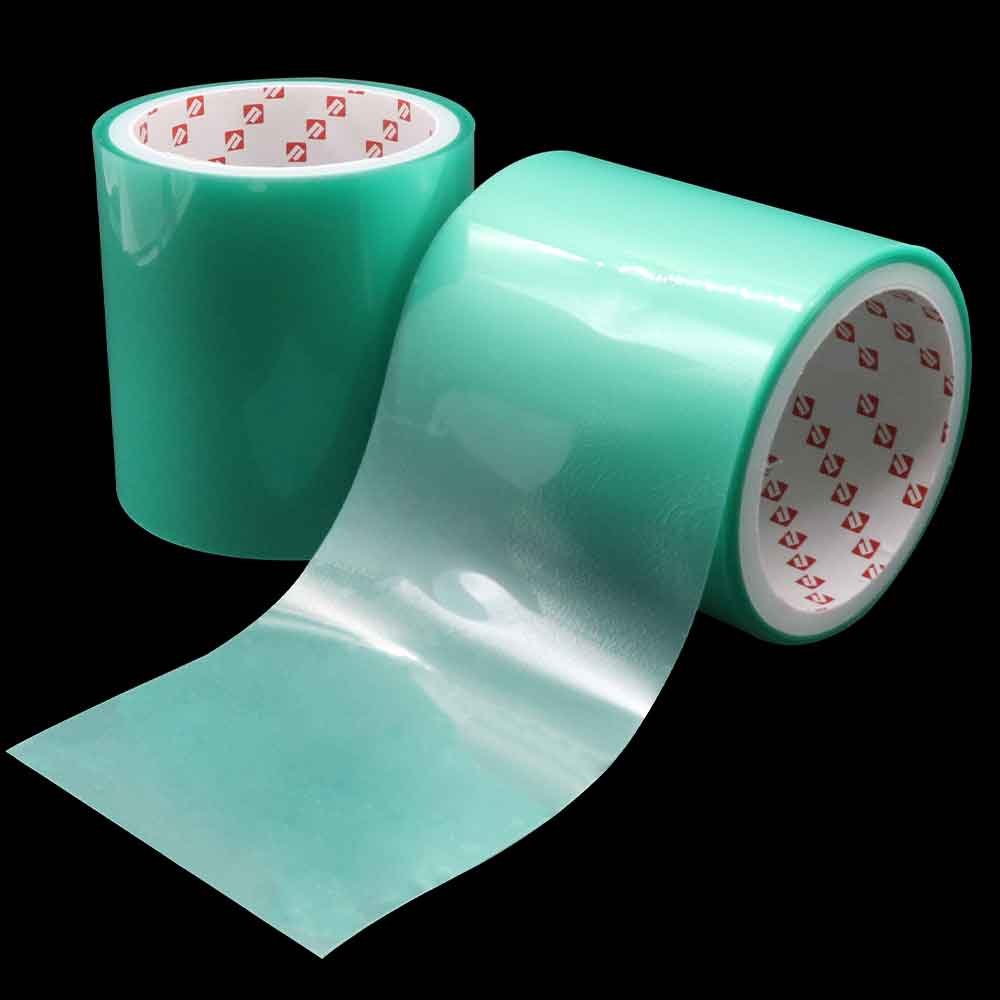

UPE ultra high molecular weight polyethylene film

application

Used in the packaging industry for medical devices, food, electronic equipment, etc.

Wear-resistant coatings for internal surfaces of mechanical equipment, conveyor systems, etc.

Used to make pipe linings, seals for valves, pumps and other fluid control equipment.

Protective wear layer for sports and protective equipment.

Good insulation and mechanical protection as cable sheath material.

Property

| Test items | Typical value | Unit | Test method |

| Backing thickness | 0.08 | mm | GB/T7125-2014 |

| Adhesive thickness | 0.05 | mm | GB/T7125-2014 |

| Total thickness | 0.13 | mm | GB/T7125-2014 |

| Adhesion to steel | ≥8 | N/25mm | GB/T2792-1998 |

| Density | 0.93~0.95 | g/cm3 | ASTM D792 |

| Molecular weight | 350~920 | 104g/mol | ASTM D4020 |

| Water absorption | <0.01 | % | ASTM D570 |

| Tensile Strength | 38 | Mpa | GB/T 1040.3-2006 |

| Bending strength | 26 | Mpa | GB/T 1040.3-2006 |

| Elongation at break | 50 | % | GB/T 1040.3-2006 |

| Compressive strength (10%) | 27 | Mpa | ASTM D695 |

| Shear strength | 33 | Mpa | ASTM D695 |

| Shore hardness | 60~63 | D | ASTM D2240 |

| Coefficient of friction | – | 0.07~0.11 | ASTM D1894 |

| Temperature resistance | ℃ | -269~90 | ASTM D4894 |

| Thermal expansion coefficient | ℃-1 | 1.5×10-4 | GB1036-1989 |

| Abrasion rate | mg | 80 | GB/T 3960-1989 |

| Dielectric breakdown strength | Kv/mm | 45 | IEC 60243-2:2001 |

| lSurface charge rate | Ohm | 1015 | ASTM D257 |

description

Product Features

1.Excellent wear resistance, good chemical stability.

2.Excellent impact resistance, low coefficient of friction and self-lubricating properties.

3.High strength and high toughness, light weight.

4.Low temperature resistance, electrical insulation properties, and environmental hygiene.

Comments

Post a Comment